HERA - SOLUTIONS IN METAL

Von der Beratung, Planung, Entwicklung, Projektierung und Werkzeugkonstruktion, der Muster- und Prototypenfertigung, der Serienfertigung bis hin zur Auslieferlogistik. Mit eigenem Werkzeugbau und dem permanenten Blick für die geforderten Qualitäten während des kompletten Produktentstehungsprozesses.

Wenn es ums Halten, Stabilisieren, Sichern und Bewegen geht, haben wir die metallische Lösung für Sie – SOLUTIONS IN METAL

Kompetenzen

Fullservice von der Planung bis zum fertigen Bauteil!

Wir sehen uns nicht nur ausschließlich als Hersteller, sondern vielmehr als strategischer Projektpartner.

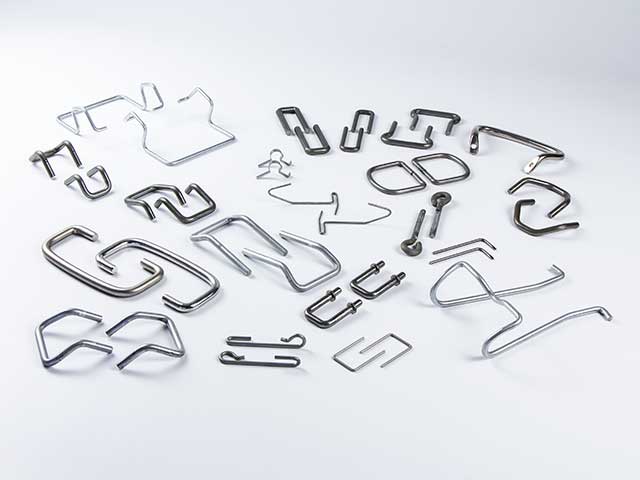

Produkte

Sicherheitsrelevante Drahtbiege- und/oder Drahtkaltumformteile, Rohrbiege- und/oder Rohrkaltumformteile, Stanz- und Stanzbiegeteile sowie Baugruppen vom einfachen Stift bis hin zu komplexen Geometrien sind unsere Leidenschaft.

Verschaffen Sie sich hier einen Einblick in unser Produktportfolio.

Unternehmen

Die Entwicklung zukunftsweisender Innovationen prägt unser Handeln seit mehr als 130 Jahren.

Erfahren Sie hier mehr über unsere Visonen, unsere Philosophie und unsere Geschichte.

Rückblick auf unser Sommerfest am 15. September 2023

In diesem Jahr hatten wir nicht nur die Familien unserer Mitarbeiter, sondern auch unsere Ehemaligen zu einem unvergesslichen Tag eingeladen.

Das Highlight des Tages waren die exklusiven Führungen, bei denen wir stolz die Fortschritte und Neuerungen der letzten Jahre präsentierten. Es war eine großartige Gelegenheit, die Entwicklung unseres Unternehmens zu teilen und einen Blick hinter die Kulissen zu werfen.

Für unsere jüngsten Gäste hatten wir eine Vielzahl von Spielgeräten vorbereitet, um sicherzustellen, dass auch sie einen spaßigen Tag bei uns verbringen konnten.

Wir möchten uns bei allen bedanken, die zu diesem besonderen Ereignis beigetragen haben, und freuen uns bereits auf kommende Veranstaltungen, um die Bindungen in unserer Unternehmensfamilie weiter zu stärken.

45 Jahre Betriebszugehörigkeit

Im August durften wir erneut ein Betriebsjubiläum feiern. Unser Technischer Leiter, Armin Schauder, feiert stolze 45 Jahre Betriebszugehörigkeit – eine beeindruckende Zeit voller Engagement und Fachkenntniss.

Herr Schauder ist nicht nur ein Experte in seinem Bereich sondern auch ein wichtiger Bestandteiel unseres Teams. Sein Einsatz und seine Erfahrung haben unser Unternehmen mitgeprägt.

Das gesamte Team gratuliert herzlich.

v.l.n.r. Uwe Ditzer, Armin Schauder, Bernd Schneider

Trikotsponsoring Altliga SG Albaum/Heinsberg

Im vergangenen Juni hatten wir die Ehre, als Sponsor die Fußball Altliga SG Albaum/Heinsberg mit neuen Trikots auszustatten. Diese Partnerschaft ermöglicht es uns, die lokale Gemeinschaft zu unterstützen und die Werte des Sports zu fördern.

Der Fußball in unserer Region repräsentiert Teamgeist und Fair Play, Werte, die wir als Unternehmen schätzen und teilen. Wir sind stolz darauf, die Mannschaft auf ihrem Weg zu begleiten und Teil dieser leidenschaftlichen Fußballgemeinschaft zu sein.

Mehr „Power“ im Fertigungsbereich Stanzen

Eine weitere Investition in die Zukunft!

Um unser Geschäftsfeld zu erweitern und den Ansprüchen unserer Kunden gerecht zu werden, wurde im Jahr 2022 ein 300 Tonnen Stanzautomat der Marke HAULICK angeschafft und im Jahr 2023 in die Fertigung übernommen.

Der Umwelt zuliebe

Eine neue Fassade am Bürotrakt ja, aber bitte nur wärmedämmend und energieeffizient! Das war unsere Vorgabe an die Albert Sommer GmbH, Spezialist für Dach und Fassade. Diese Vorgabe wurde eindrucksvoll und farblich modern im Jahr 2022 umgesetzt.

Zusätzlich wurden Wallboxen für die Elektromobilität von Besuchern und Mitarbeitern angebracht!

50 Jahre - Ein HERA Urgestein

Das macht Ihm so schnell keiner nach.

Auch wenn es sich viele jüngere Arbeitnehmer nicht vorstellen können - Dieter Fischer aus dem „Fertigungsbereich Drahtbiegetechnik“ trat am 01.09.1972 in unser Unternehmen ein und feierte somit jetzt sein 50-jähriges Betriebsjubiläum!

"Gerade heute, wo die durchschnittliche Betriebszugehörigkeit nicht einmal 12 Jahre beträgt, ist das eine bemerkenswerte Zeitspanne. Umso mehr wissen wir die Loyalität und das Engagement unserer Mitarbeiter, in allen Abteilungen und jeden Alters, sehr zu schätzen.", so Bernd Schneider.

Im Namen des gesamten HERA-Teams gratulierten, mit einem entsprechenden Präsent, Geschäftsführer Bernd Schneider und Betriebsratsvorsitzender Uwe Ditzer.

v.l.n.r. Uwe Ditzer, Dieter Fischer, Bernd Schneider

Team HERA - AOK Firmenlauf 2022

Gemeinsam weiterlaufen – Zusammen in die Zukunft!

Nach 2 Jahren virtuellen Firmenlauf, fand der 19. Siegerländer AOK-Firmenlauf am 22.06.2022 endlich wieder in der Innenstadt von Siegen statt. Corona Pandemie bedingt wurde die Teilnehmerzahl auf ca. 5.000 beschränkt.

Auch in diesem Jahr organisierte unser Einkaufsleiter Herr Lippert (mit Kappe), das eine sportliche Abordnung unseres Unternehmens – das Team HERA – am Firmenlauf teilnahm. Selbstverständlich wurden auch in diesem Jahr die Trikots, sowie ein anschließendes gemütliches Zusammensitzen mit Abendessen, von unserer Geschäftsführung gesponsert.

Durch die zahlreichen Zuschauer und den 15 Live-Bands am Straßenrand euphorisiert, war sich – das Team HERA – einig: Wir sind im nächsten Jahr auch zum 5. Mal in Folge, dann beim 20. Siegerländer AOK Firmenlauf, dabei und motivieren noch weitere Arbeitskollegen/innen zum Mitmachen!

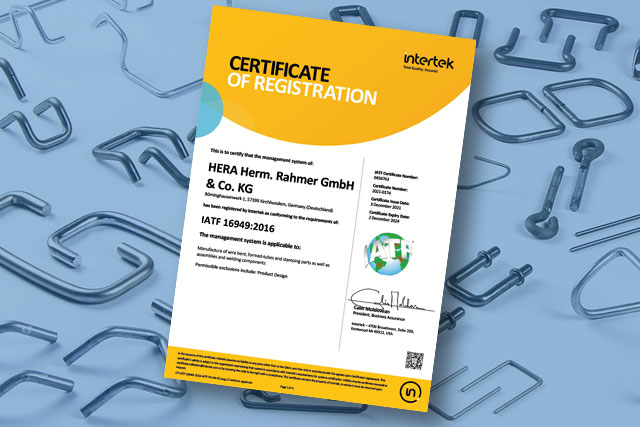

Starke Team Leistung – IATF 16949:2016

Gemeinsam arbeiten – Zusammen in die Zukunft!

Die Herausforderung hörte sich groß an, die Begeisterung war am Anfang eher klein. Doch nachdem die Forderung der IATF 16949:2016 den einzelnen Abteilungen zugetragen wurde, waren alle Kolleg*innen der Meinung - so arbeiten wir doch schon seit Jahren, wir müssen es nur niederschreiben.

Gesagt, getan! Die einzelnen Teams begaben sich unter der Leitung von Ralf Galler, Leiter des Qualitätsmanagements, 2020 an die Arbeit.

Die Auditierung fand im Herbst 2021 statt. Mit der Übergabe der Zertifizierungsurkunde 2021-0174 vom 03. Dezember 2021 wurde die starke Team-Leistung aller Mitarbeiter*innen belohnt.

Geschäftsführer Bernd Schneider bedankt sich bei seinem „HERA-Team“!

Team HERA - AOK Firmenlauf 2021

Gemeinsam weiterlaufen – Zusammen in die Zukunft!

Der "Siegerländer AOK-Firmenlauf" ist seit 18 Jahren mehr als eine Sportveranstaltung, er ist das größte Breitensportevent in Südwestfalen. Über 8.000 Starterinnen und Starter laufen hierbei eigentlich durch die Straßen Siegens.

Im Jahr 2021 mussten, wie auch im Jahr 2020, die Bedingungen an die Corona-Pandemie angepasst werden. Die Teilnehmerinnen und Teilnehmer absolvierten daher die Mindestdistanz von 5,5 Km im Zeitraum vom 15. September bis 02. Oktober, wo und wann sie wollten.

Organisiert durch unseren Einkaufsleiter Jörg Lippert (Start-Nr. 3664), nahm zum dritten Mal in Folge auch eine sportliche Abordnung unseres Unternehmens - das Team HERA - am Firmenlauf teil. Am 01. Oktober traf sich unser Team zum laufen, walken und gehen, rund um die Breitenbach-Talsperre.

Trikots, sowie ein anschließendes gemütliches Zusammensitzen mit Abendessen, wurden von unserem Geschäftsführer Bernd Schneider (Start-Nr. 3668) gesponsort.

45 Jahre Teil des Teams

Seinem Arbeitgeber mehr als vier Jahrzehnte die Treue zu halten ist, gerade in der heutigen Zeit, sicher nicht alltäglich.

Umso mehr freut es uns, dass wir in diesem Jahr gleich drei Teammitgliedern zu diesem Jubiläum gratulieren dürfen. Peter Gruschka (Gewindetechnik), Udo Hermes (Stauch- und Kaltfließpresstechnik) und Thomas Köhldorfner (Logistik) gestalten seit 45 Jahren das Werden unseres Unternehmens mit.

„Unsere Mitarbeiter, unser wichtigstes Kapital - und auf die drei Herren bezogen, eine sehr langfristige Investition, die sich definitiv bezahlt macht“, so Bernd Schneider (Geschäftsleitung), der den Jubilaren mit einem Präsent gratulierte.

Das gesamte HERA-Team schließt sich natürlich den Glückwünschen an!

v.l.n.r. Peter Gruschka, Udo Hermes, Bernd Schneider und Thomas Köhldorfner

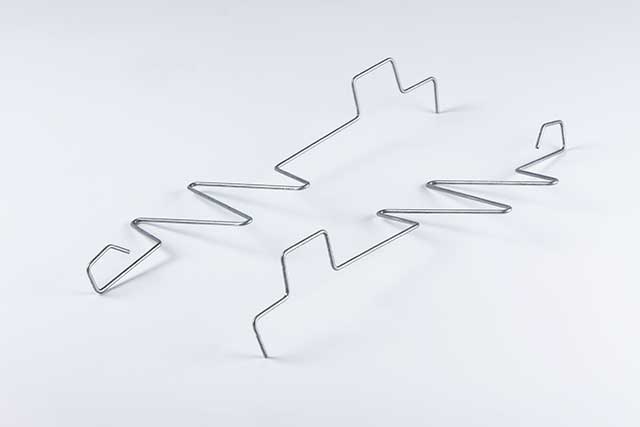

Brennholz einfach und sicher abdecken

Erfindergeist prägt seit jeher das Werden unseres Unternehmens. Wie sie in unserer Firmengeschichte nachlesen können, waren es nicht immer die ganz großen Erfindungen die unser Handeln bestimmt haben. Kleine Dinge, die das Leben leichter machen und einfache Probleme lösen, haben es uns angetan.

Unser patentierter "Holz-Planen-Spanner" reiht sich somit nahtlos in diese Geschichte ein!

Schluss mit flatternden und verschwundene Holz-Abdeckplanen über dem frisch gestellten Brennholz! Einfach in der Anwendung, sicher, wiederverwendbar und kostengünstig sorgt der stabile Draht für genügend Vorspannung um die Plane da zu halten wo sie hingehört. Das ideale Produkt für alle die sich mit dem Thema Brennholzlagerung und den dazugehörigen Materialien beschäftigen.